Tea Waste Desiccant: A Sustainable Replacement

Tea Waste Desiccant transforms tea waste into a sustainable product with the aim of replacing non-biodegradable desiccant worldwide.

Have you ever wondered about those little “do not eat” packages of silica that accompany many shipped goods? That’s desiccant (from Latin, to “make thoroughly dry”)—widely used to absorb moisture from the air and reduce the humidity inside sealed containers. Desiccants are typically made from non-biodegradable materials like silica, but first-year student Qiting Fang reimagined a more sustainable solution. Tea Waste Desiccant is a speculative company aiming to transform tea leaf waste into natural desiccant and replace common non-biodegradable silica desiccant worldwide.

The Guangdong Province consumes

approximately 250,000 tons of tea per year.

Qiting found inspiration for her project while observing the deeply-rooted tea culture in her native Guangdong Province. “Tea drinking is a prevalent practice in the region and produces a considerable amount of waste," she explains. According to Qiting's research, Guangdong's tea consumption amounts to about 250,000 tons per year. Most of the corresponding tea leaf waste is disposed of by landfill and incineration. Qiting saw an opportunity to make something sustainable (and surprisingly profitable!) with this waste byproduct.

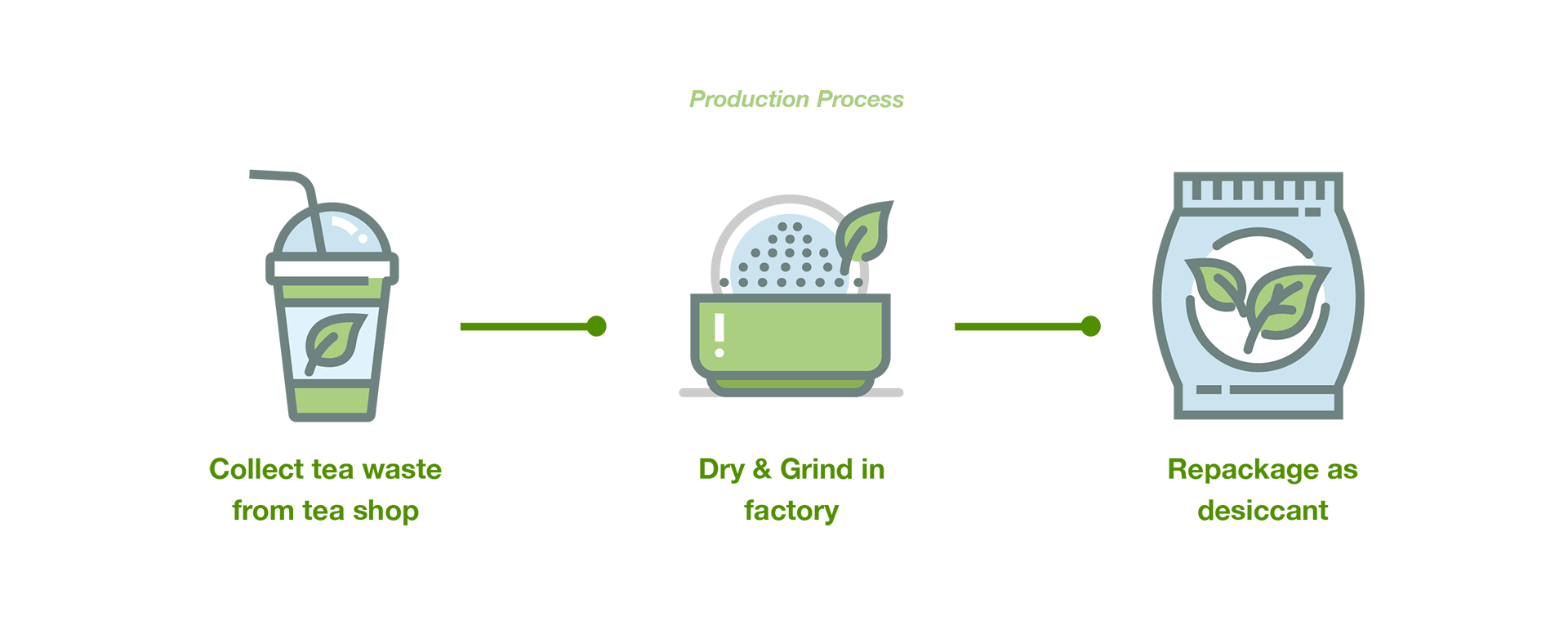

"It is worth noting that tea leaf waste has a high recycled value, which can be transformed into a new product—natural desiccant—and be profitable in the global desiccant market," Qiting shares. Noting the dried leaves’ naturally absorbent properties, she designed a system to collect tea waste from local tea shops, next to be dried and ground in a factory, and finally packaged as natural desiccant.

Compared to the most commonly used desiccants (like silica gel) currently on the market, dried tea desiccant is made of 100% recycled natural materials, harmless to people and the environment, and fully biodegradable.

Qiting designed Tea Waste Desiccant as a business model that thrives on the free collection of tea leaf waste from tea shops, reusing this waste to produce natural desiccant, and selling it to packaging production factories for profit. Meanwhile, Tea Waste Desiccant also considers rewarding tea shops to prompt more businesses to participate in the process. Check out Qiting’s business model diagram below:

From the Global Pharmaceutical Desiccant Market Forecast 2019-2027, the predicted revenue by 2027 is approximately 190 million dollars. "There is significant development potential for tea desiccant," Qiting says. "In the future, tea desiccant could be used widely in different industries—food, pharmaceutical, packing, electronics, and bottle manufacturing.”

Qiting created Tea Waste Desiccant during the first-semester course, Design for Sustainability and Resilience, taught by Suma Reddy. Qiting says of her "entrepreneurship-as-activism" project, "I defined a problem in my familiar food space, conducted research, and designed a solution that is sustainable."